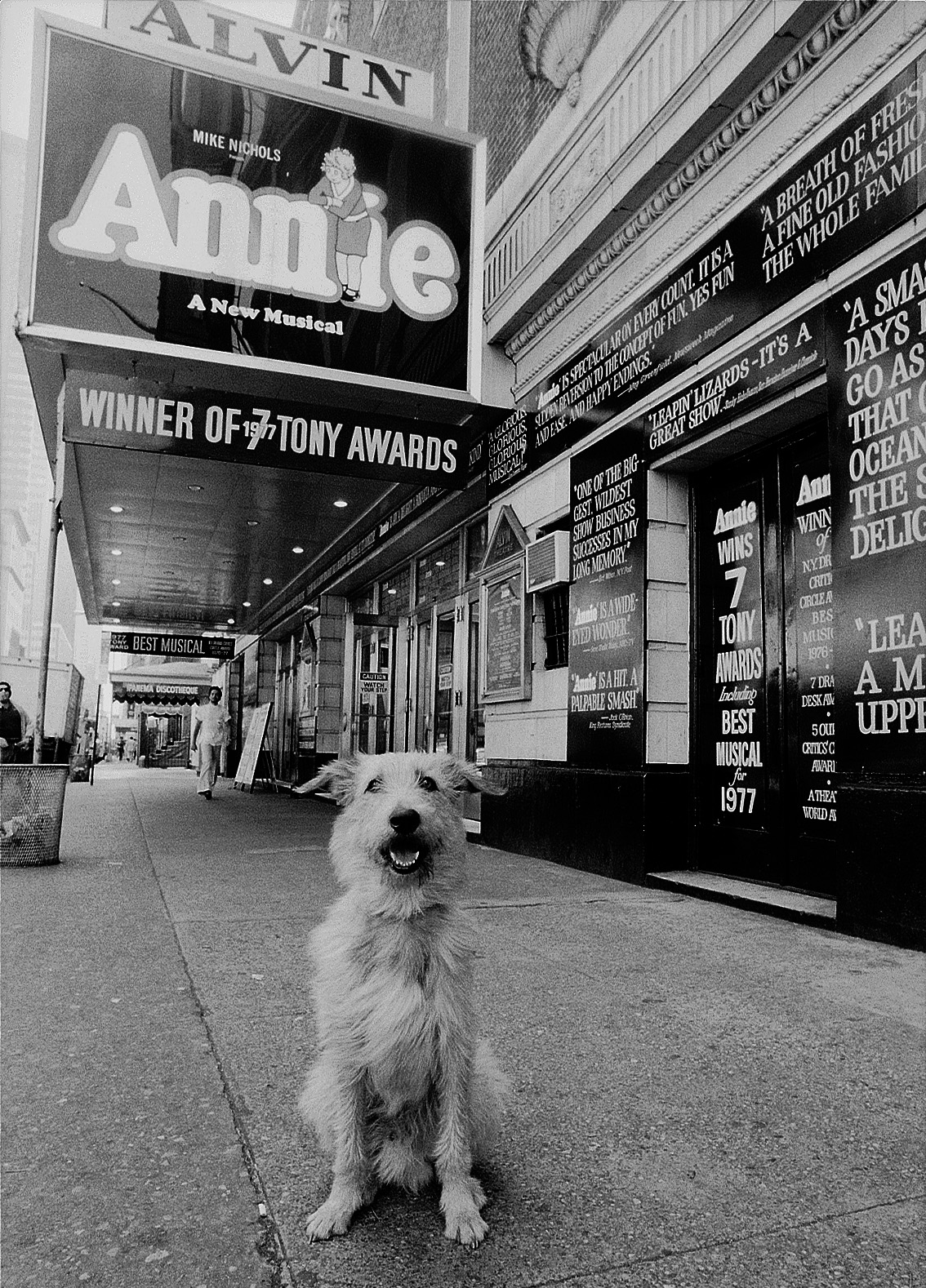

"Sandy" the canine star of the hit Broadway show "Annie."

Sandy clay model is built on a skeletal wire frame for strength.

Clay model.

Clay model.

Clay model finishing touches.

Wet toweling protects the clay model during the mold process.

Marking to place shims.

The model is covered in clay as a separator.

Applying the clay.

Shims are implanted to allow the plaster and rubber mold encasement to be easily removed.

Mixing plaster.

Plaster is applied to the resulting form.

Arranging the support bars.

Support bars in place.

Removing the plaster shell off the model to expose the filler materials.

Filler material to be removed.

Liquid rubber is mixed and poured into two spouts filling the void as it forms around the clay model.

Total removal of plaster cast.

Removing the rubber from the clay model.

Finished. Ready for the wax application.

Wax was painted onto the rubber imprint and cooled.

The artist does finishing details using heated metal tools.

Finishing touches.

Molten bronze being poured into prepared ceramic shell mold.

A support bar is inserted in the base.

Applying the patina or color. Chemicals are painted on using a blowtorch that heats the metal.

Waiting for approval.

Ready to go home !

"Sandy" the canine star of the hit Broadway show "Annie."

Sandy clay model is built on a skeletal wire frame for strength.

Clay model.

Clay model.

Clay model finishing touches.

Wet toweling protects the clay model during the mold process.

Marking to place shims.

The model is covered in clay as a separator.

Applying the clay.

Shims are implanted to allow the plaster and rubber mold encasement to be easily removed.

Mixing plaster.

Plaster is applied to the resulting form.

Arranging the support bars.

Support bars in place.

Removing the plaster shell off the model to expose the filler materials.

Filler material to be removed.

Liquid rubber is mixed and poured into two spouts filling the void as it forms around the clay model.

Total removal of plaster cast.

Removing the rubber from the clay model.

Finished. Ready for the wax application.

Wax was painted onto the rubber imprint and cooled.

The artist does finishing details using heated metal tools.

Finishing touches.

Molten bronze being poured into prepared ceramic shell mold.

A support bar is inserted in the base.

Applying the patina or color. Chemicals are painted on using a blowtorch that heats the metal.

Waiting for approval.

Ready to go home !